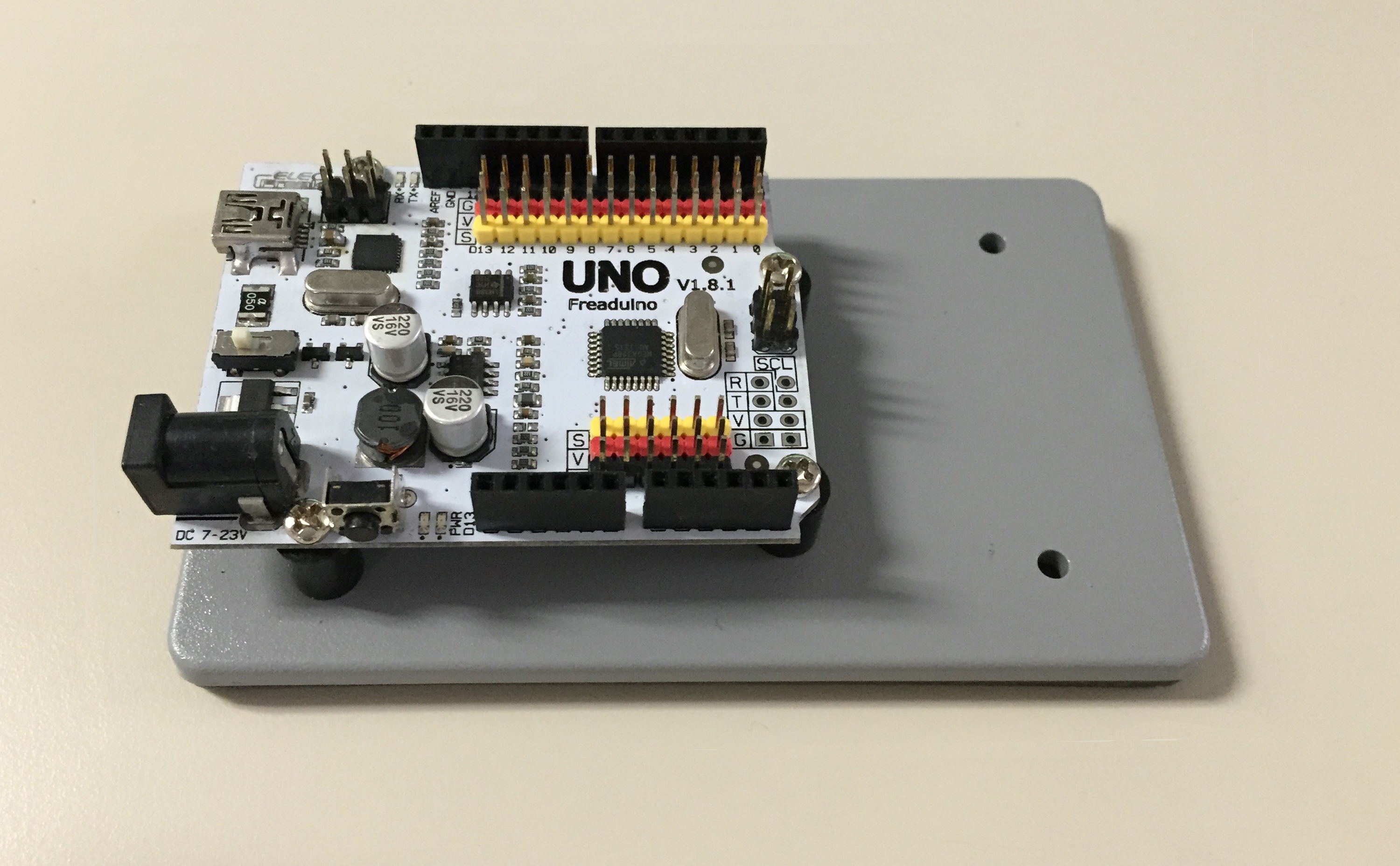

Top view of Freaduino and base.

Top view of Mega and base.

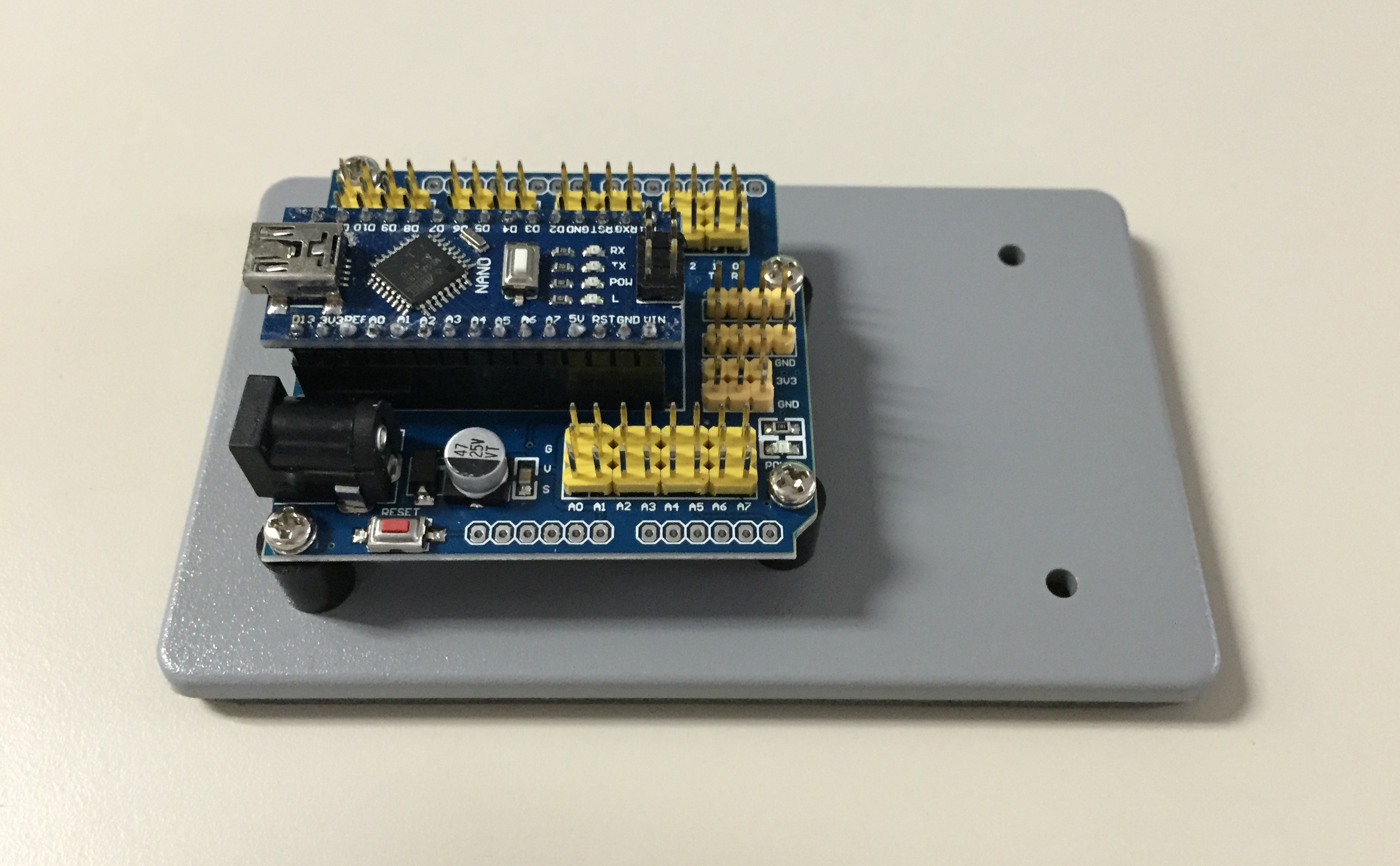

Top view of Nano, I/O extension, and base.

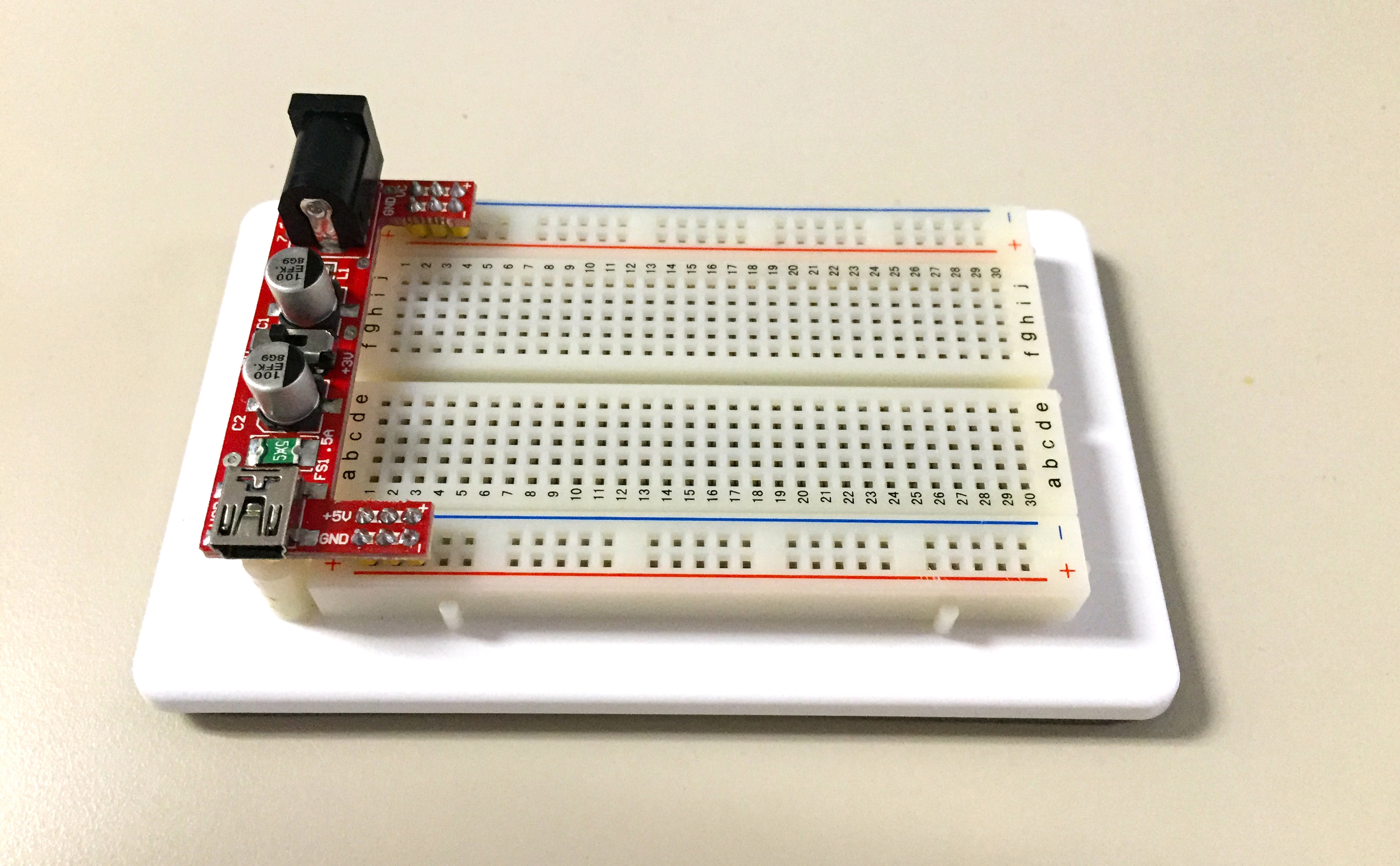

Top view of small breadboard, power supply, and base.

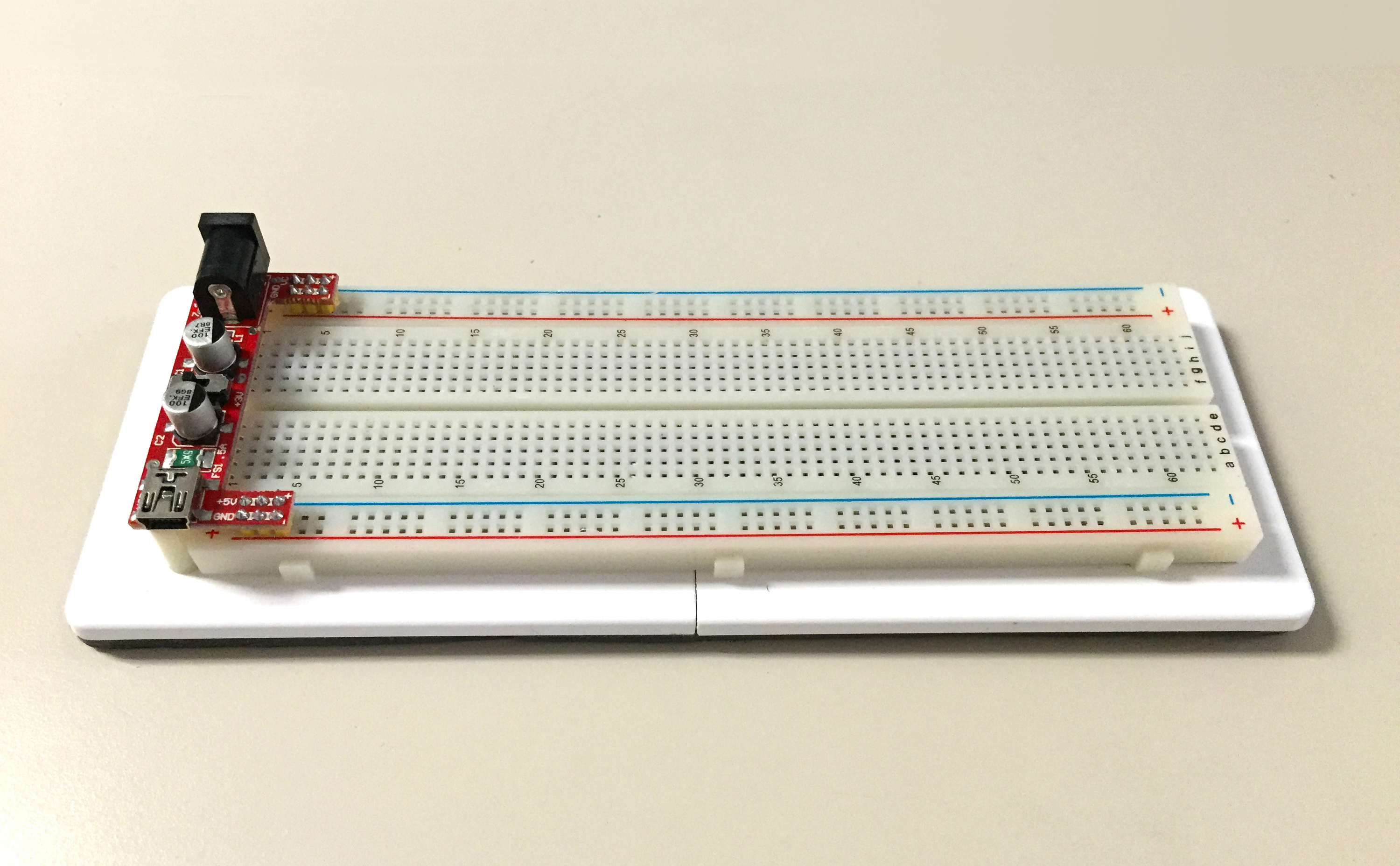

Top view of large breadboard, power supply, and base.

Top view of DDS function generator and base.

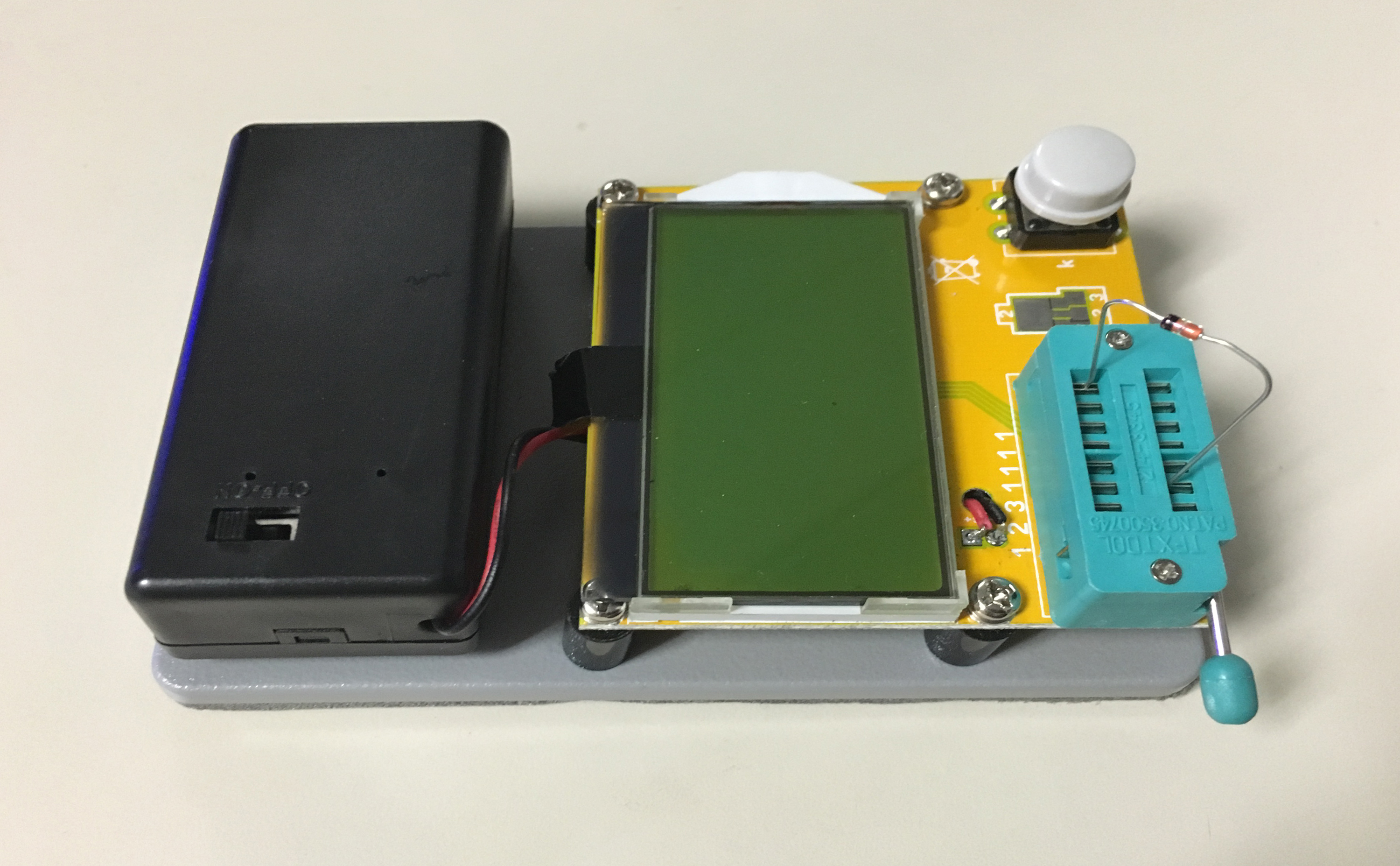

Top view of component tester with battery box and base.

The battery box is held in place with double-sided foam tape.

The battery box wires are soldered to the PCB and replace the original clip-on 9V connector.

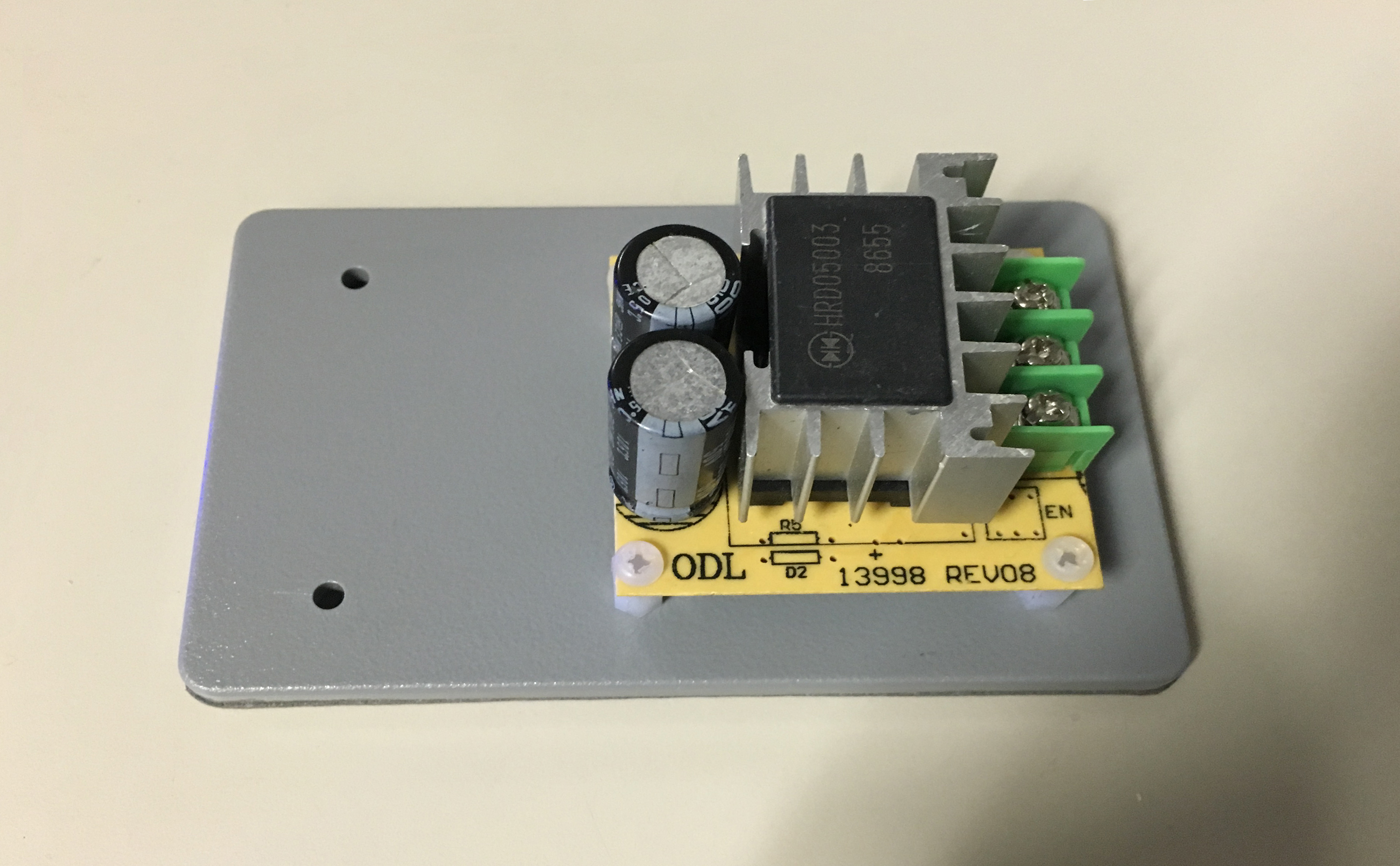

Top view of variable regulated DC power supply and base.

This board and the next one are attached to the base with nylon hex standoffs and screws.

Top view of DC-to-DC step down converter and base.

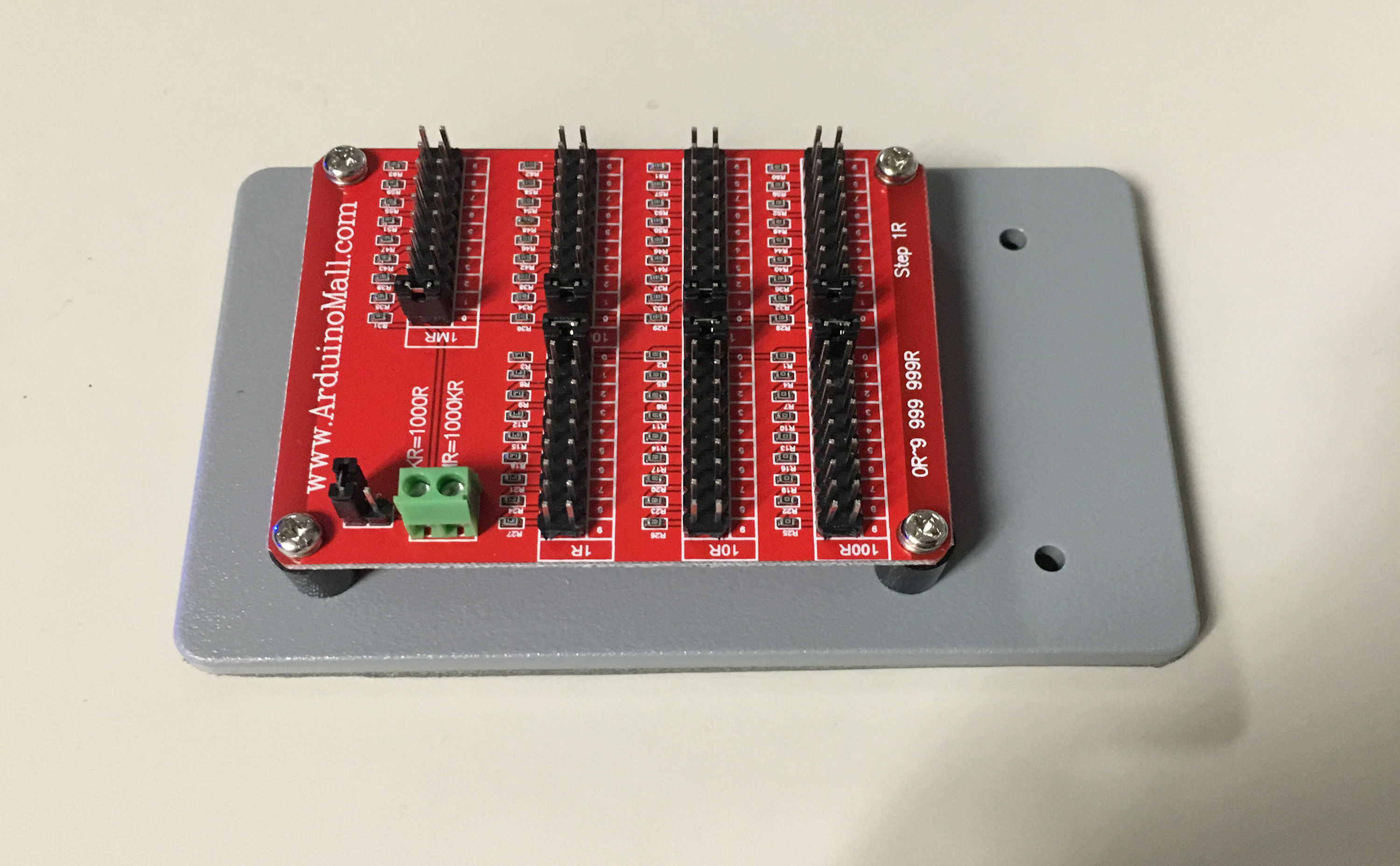

Top view of seven-decade resistance board and base.

Top view of four-decade capacitance board and base.

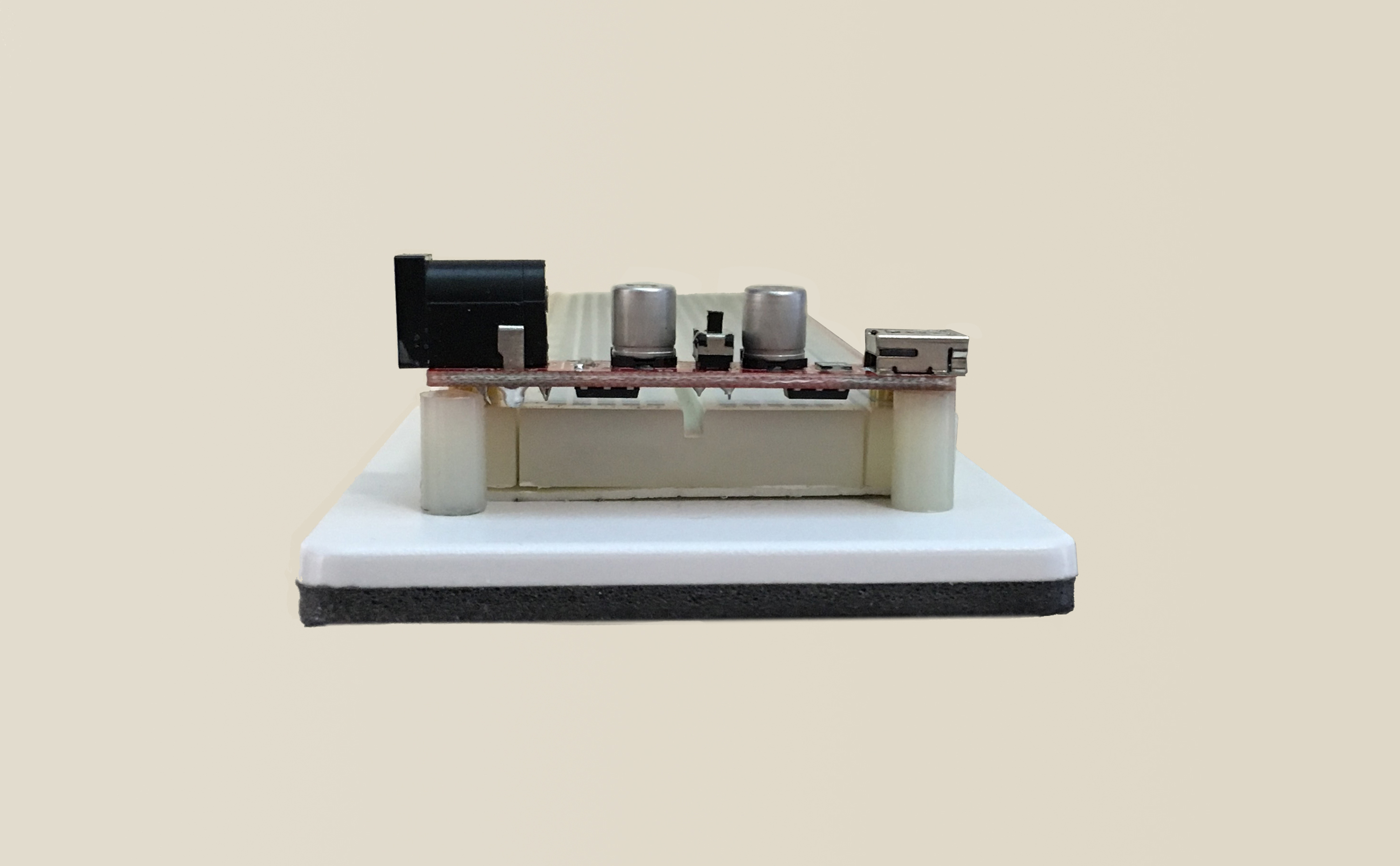

End view of large breadboard and base, showing power supply supports.

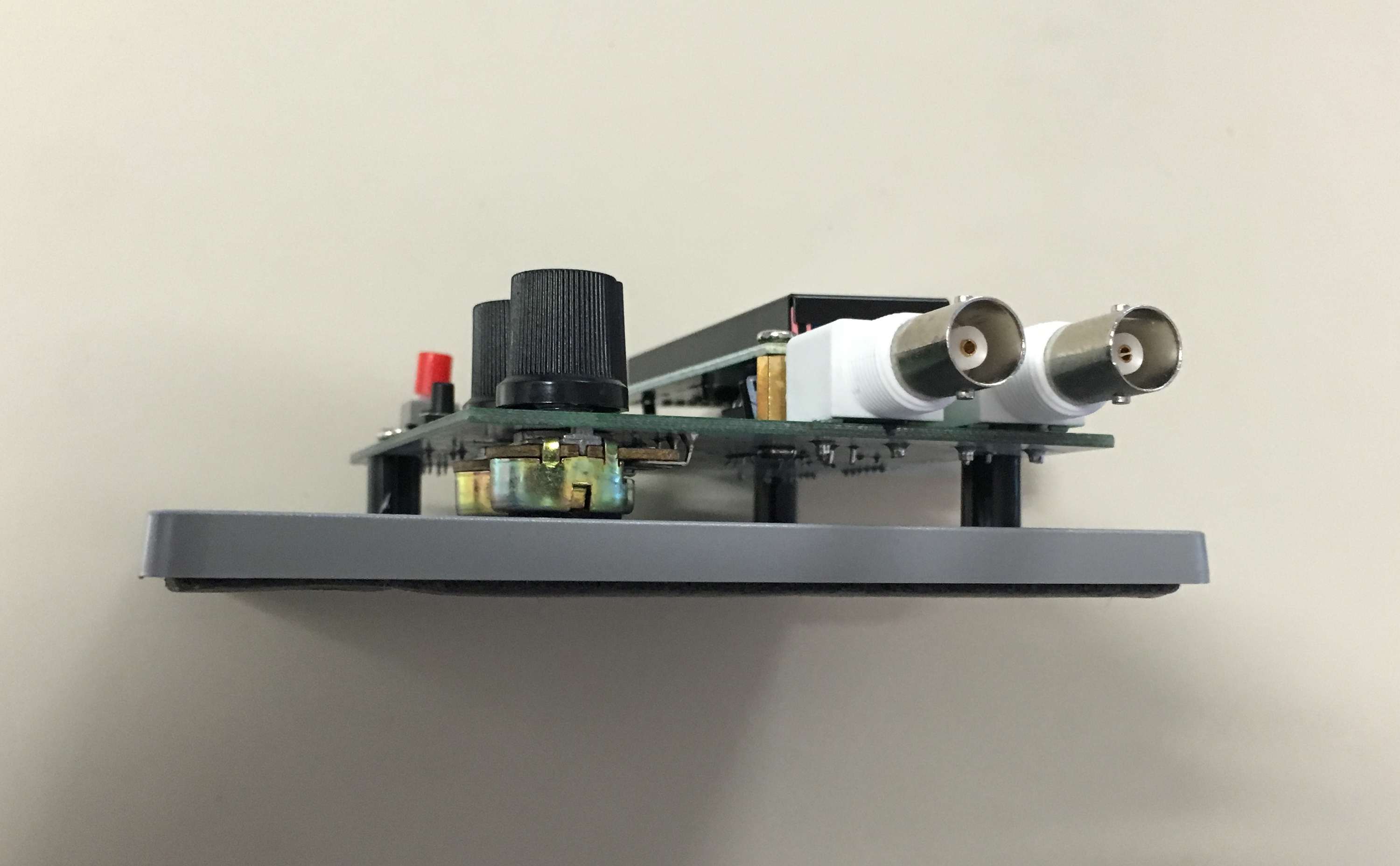

End view of DDS function generator and base, showing supports, one of which is a potentiometer.

Bottom view of Freaduino base.

Bottom view of Mega base.

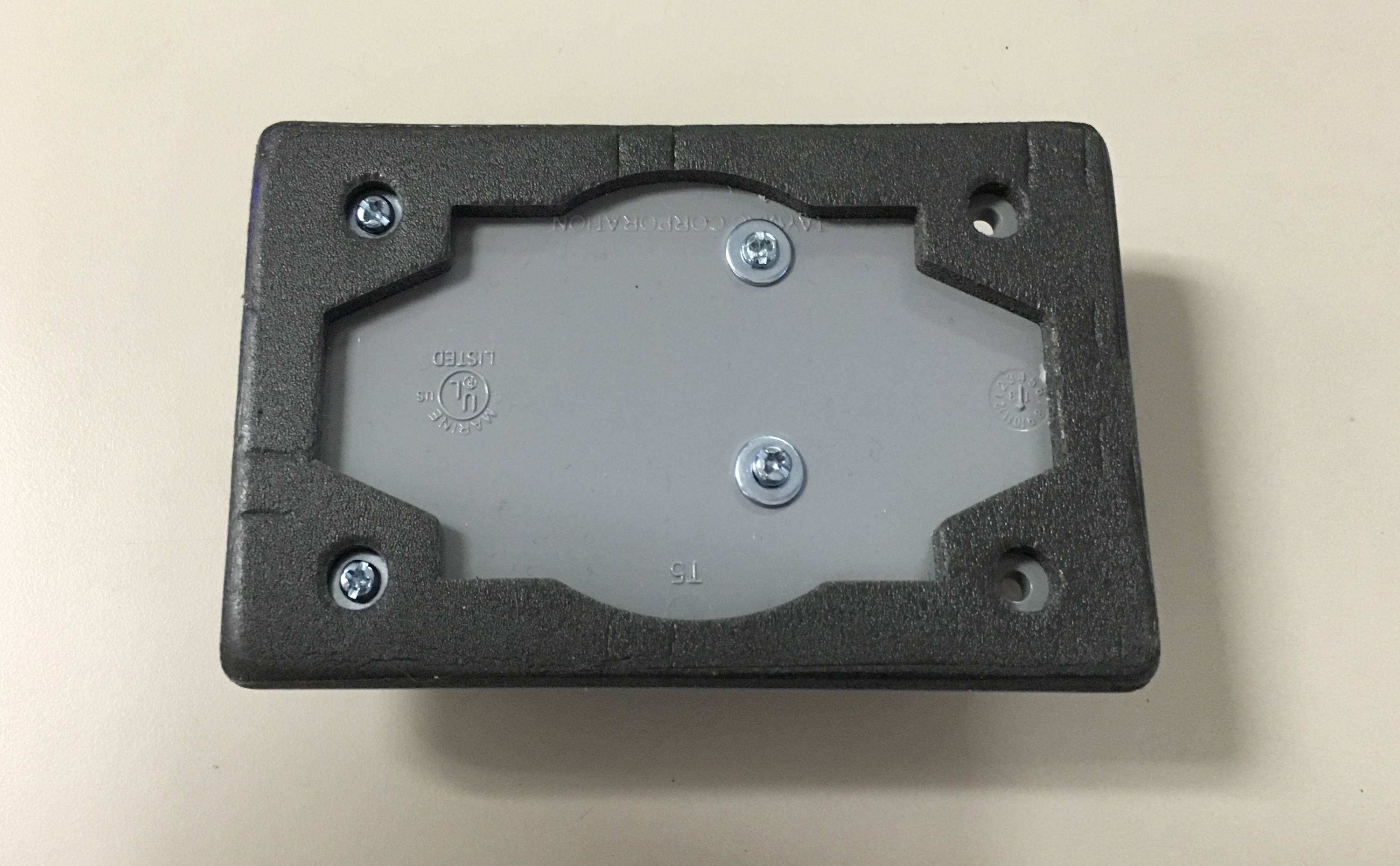

Bottom view of large breadboard base.

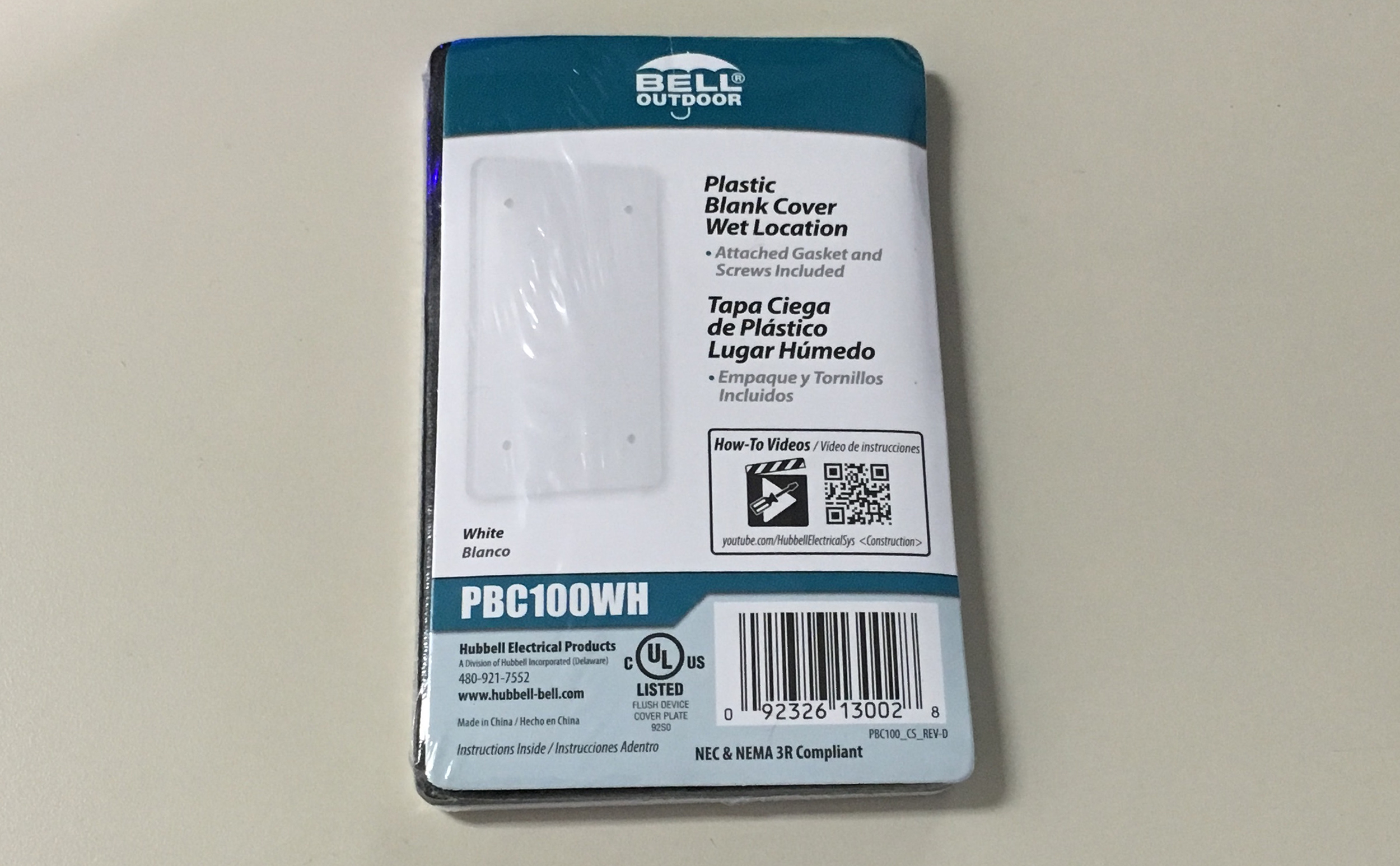

Package for small, white cover plate.

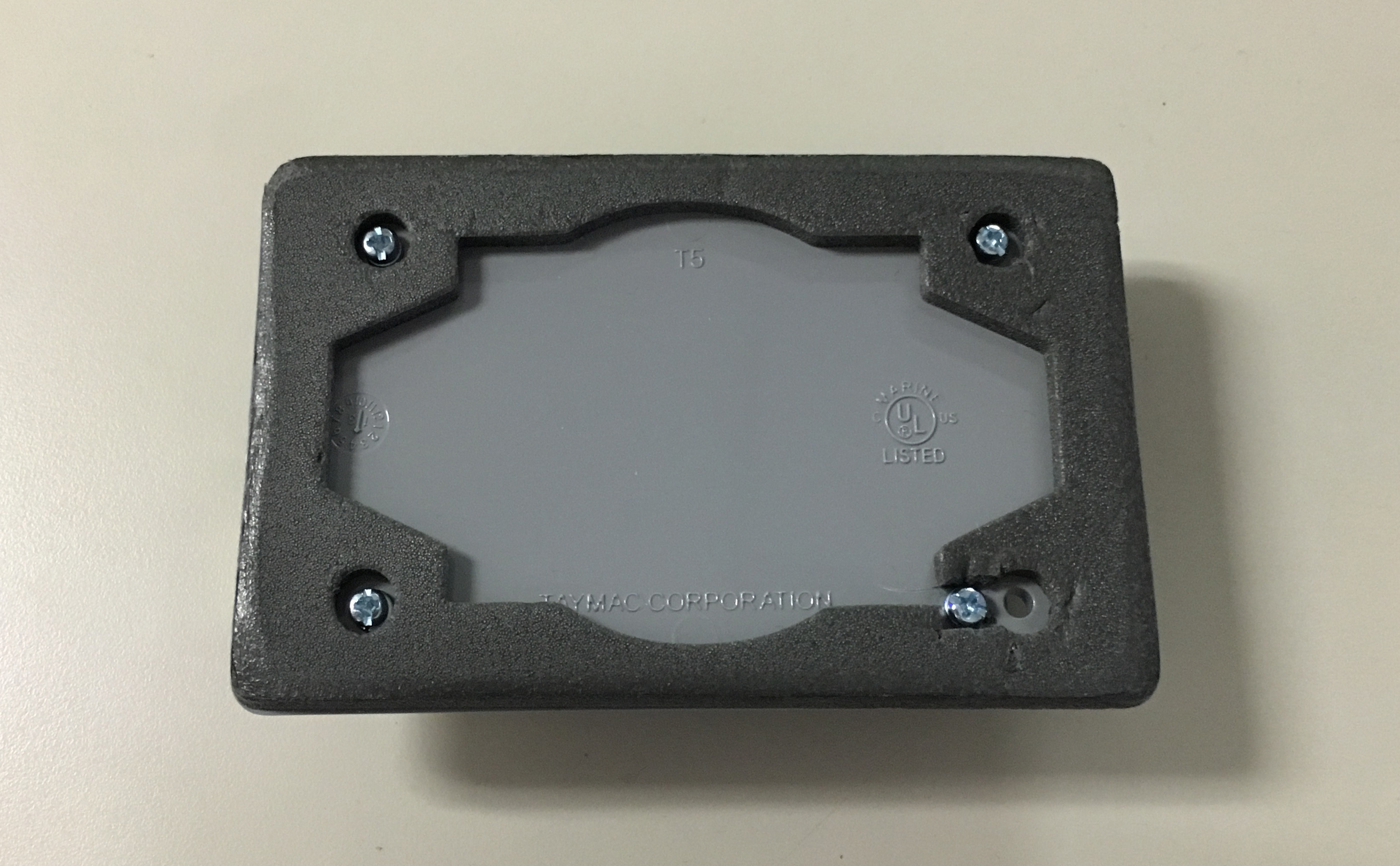

Package for large, gray cover plate.